Liner Diameter Measurement (LDM)

The main engine is the driving force of the ship and any damage to it can make the ship un-seaworthy and can have a substantial commercial and financial impact on the Owners.

Owners/Operators are constantly experiencing excessive Liner wear due to:

- Running on compliant, low-sulphur fuels as a result of the Emissions Control Regulations in-force from 2020

- Im-proper Cylinder oil lubrication (feed rate and/or BN)

- Slow steaming

- Off-spec fuels with increased number of Cat fines

- Poor on-board fuel handling system (purifiers, filters etc)

In response to the continuous growing demand, our company is offering the Liner Diameter Measurement (LDM) service in which an advanced technological instrument is used to perform in-situ, high precision Cylinder Liner wear measurements.

LDM

Benefits

– Fast service which requires only 1-operator to measure the whole engine (1 to 1.5 hrs per cylinder) without removing the Cylinder head

– High precision measurements which do not rely in traditional man-made measurements in confined spaces using micrometer

– Can be used in all 2-stoke Engines (500-980 mm bore)

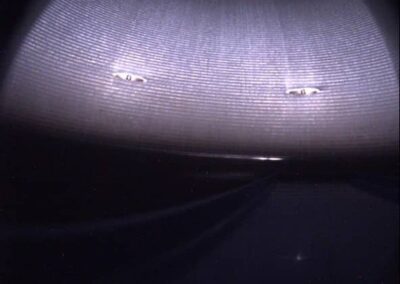

– High resolution photos of the inner liner surface and ring packs which can be used to detect:

-

- scuffing

- bore polishing

- cold corrosion

- uneven cylinder oil distribution

- fuel injector erosion

- cracked exhaust valve heads

– Can be used as either a pre-dry docking inspection or a continuous condition monitoring service, acting proactively and enabling the extension of the Liner lifetime or the planned replacement of the unit in a cost-efficient manner

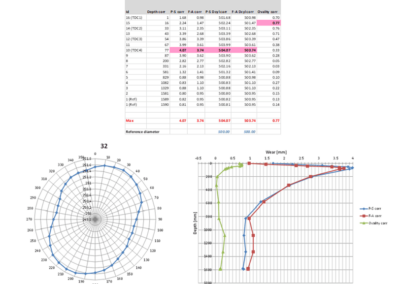

– Highly skilled and fully trained technicians providing thorough technical reports with condition assessment of each unit including wear, wear rate and ovality figures

Get A Quote